What we offer

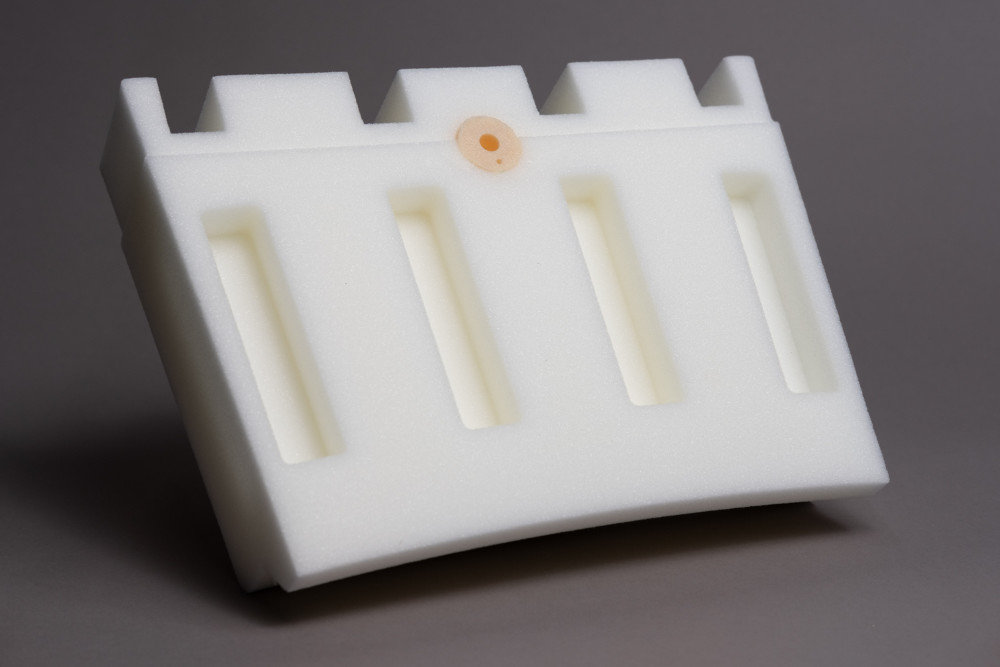

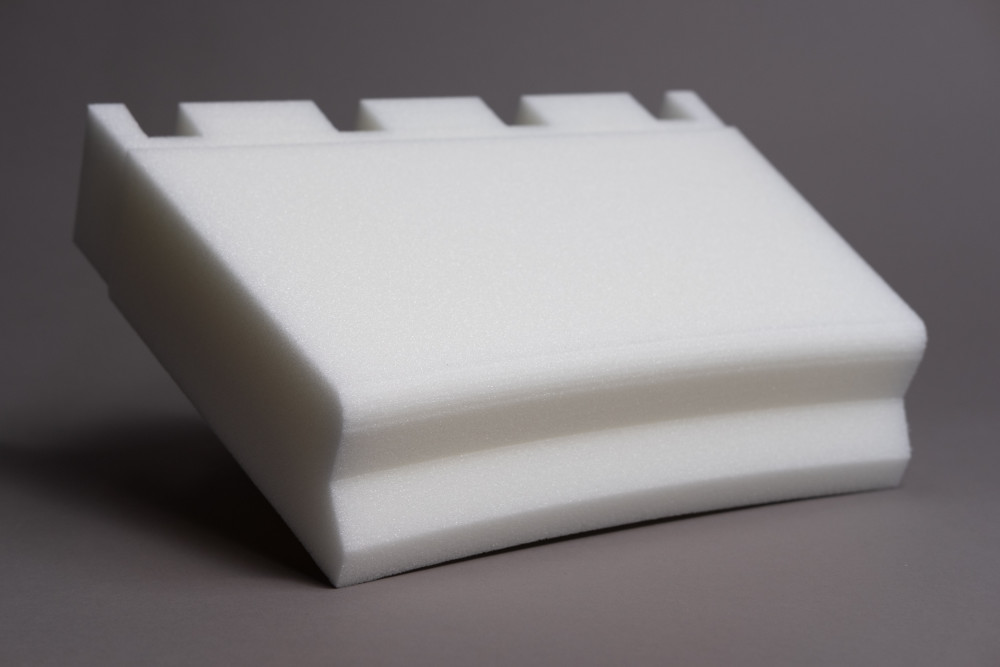

For cost effectively producing blocks or complex shaped parts from sheet and plate materials, MSA Manufacturing has invested in both 3 and 5 axis CNC milling and waterjet cutting machines.

- 3 Axis (Small Parts) CNC Milling machine: Bed envelope: 400 x 300 x 250 mm.

- 3 & 5 Axis CNC waterjet cutting machine – Bed Envelope: (L) 3000 x (W) 2000 x 100mm (max) sheet thickness. Workable area reduces in 5 axis mode, depending on part shape size.

- Intricate shapes can be accurately cut.

- Fumeless, heat free cutting process, so no stress, dimensional change or heat damage to materials.

- Sheet materials can be ‘nested’ and waste can be minimized, so is a very cost effective process.

- Plywood & Cork

- Mild steel & alloys

- Phenolic sheet

- Fibreglass laminate sheet & E-glass plate

- Carbon fibre plate materials

- Engineering plastic sheet

- Ballistic plate materials

Any specific material requirements needed for a project, not listed above, can be quoted to order.

For more materials visit our Materials Processed page.

What we offer

Cutting parts from sheet

For cost effectively producing blocks or complex shaped parts from sheet and plate materials, MSA Manufacturing has invested in both 3 and 5 axis CNC milling and waterjet cutting machines.

The extensive range of wood, metal, engineering plastic and monolithic high performance composite sheet and plate materials that can be accurately machined by MSA include:

Any specific material requirements needed for a project, not listed above, can be quoted to order.

Milling and waterjet cutting

- 3 Axis (Small Parts) CNC Milling machine: Bed envelope: 400 x 300 x 250 mm.

- 3 & 5 Axis CNC waterjet cutting machine – Bed Envelope: (L) 3000 x (W) 2000 x 100mm (max) sheet thickness. Workable area reduces in 5 axis mode, depending on part shape size.

- Intricate shapes can be accurately cut.

- Fumeless, heat free cutting process, so no stress, dimensional change or heat damage to materials.

- Sheet materials can be ‘nested’ and waste can be minimized, so is a very cost effective process.

What we give our customers

Reliable, consistent quality service

A consistently high quality, reliable service is provided by the MSA team using robust ISO 9001 management systems and QA processes. From initial contact right through to the unpacking of kits and using parts on the shop floor, MSA ensures that it provides customers with positive ’Moments of Truth’ outcomes at every key touch point.

Time & cost saving material solutions

As part of the project scoping and assessment process, MSA looks at clever ways to save customers time and money where possible.

Independent UK supplier benefits

Being independent, MSA is able to offer complete supply chain flexibility to fulfil orders, using either approved materials sourced by MSA, or free issued materials from a customer’s supply chain.